Mack Valves

Mack valves supply to various industry sectors including the Water Management, Cryogenic, Industrial/Steam, Mining and Water Management industries. Mack Valves are cryogenic valve manufacturers specialising in the manufacture of Liquid Cylinder Valves, Ball Valves, Globe Valves and Safety Valves.

- Automatic Control Valve (ACV) (1)

- Flow Switches (1)

- Cryogenic / Gas Check Valves (4)

- Cryogenic / Gas Diverter Valves (3)

- Cryogenic / Gas Globe Valves (3)

-

33 Series – Automatic Control Valve

Type: 33 SERIES

Working Pressure: 35 – 3500 kPaThe new 33 Series range comes standard in ductile iron, FBE coated, and is available in sizes from 50mm to 300mm. It can be used for a whole range of liquid mediums including potable water, seawater, aviation fuel, diesel and many others, and has been certified to AS4020 for products in contact with drinking water. Specialist application pilot systems allow the valve to be used in all applications from water level management, to pump and flow control.

Body Material: Trim Material: Flange Drilling: Special Feature: Pilot Configuration: Size: 6 – Ductile Iron 2 – Bronze

4 – Stainless steel00 – Undrilled S – Standard 11 – Rate of Flow 050 1A – ANSI 150 C – Anti-Cavitation 13 – Sustaining/Relief 080 1U – AS4087 PN16 V – V-Port Trim 18 – Pressure Reducing 100 2U – AS4087 PN21 F – Viton Elastomers 22 – Main Valve Only 150 3A – ANSI 300 I – Visual Position Indicator 23 – Ball Float 200 3U – AS4087 PN35 26 – Solenoid 250 DE – Table D/E 28 – Altitude 300 F0 – Table F 34 – Twin Solenoid NOTES:

1) Maximum flow is based on velocity of 6 m/s

2) Recommended maximum velocity for continuous service is 6 m/s

3) Recommended maximum velocity for intermittent service is 7.5 m/s

4) Recommended maximum velocity for momentary service is 14.0 m/s

5) Cv units are L/sec per √KPa

-

FS Series – Flow Switches

Type: FS SERIES

MWP: 2000kPaTwo basic models available, direct switching 2-wire model and time delay 3-wire type, both suitable for voltages 24-240v AC and 24-115v DC.

Flow Switch – Direct Acting

Base No: Body Material: Pilot Configuration: Size: FS 1 – Bronze DA – Direct Acting 025 FS 1 – Bronze DA – Direct Acting 032 Flow Switch – Micro Switch

Base No: Body Material: Pilot Configuration: Size: FS 1 – Bronze MS – Micro Switch 025 FS 1 – Bronze MS – Micro Switch 032 Flow Switch – Switch Time Delay

Base No: Body Material: Pilot Configuration: Size: FS 1 – Bronze TD – Time Delay 025 FS 1 – Bronze TD – Time Delay 032 FEATURES AND BENEFITS:

- Seal-less design – eliminates potential leaks – no seals to wear or maintain

- Both models fit pipe sizes 25mm and upwards; “one size fits all”

- Compact profile – fits in tight spaces – does not restrict pipeline design

- Standard bronze and stainless steel construction – corrosion resistant for long trouble-free life

- SSL listed – accepted by insurance companies for fire service systems

- Multifunctional circuit board – user adjustable for various operations or voltage

- Australian designed and manufactured – custom designs or material options available.

Accredited To Quality Assurance AS/NZS ISO 9001:2015

-

6E Series Type 4 – Cryogenic/Check valves

6E Series Type 4 – Check Valves

Material: Bronze, Stainless steel Media: Cryogenic, Steam, Water, Air & Gases Size Range: 15mm to 50mm Ends: BSPT, NPT, Socket Weld, ANSI 150/300 Working Temperature: -196°C to +120°C Max Working Pressure: 5,000 Kpa Standards: Degreased, packed and labelled for Oxygen Service (ASTM G93)

Design in acc. EN12516 part 1&2, AS1210, EN1626

Ends: ISO 7-1, ASME B1.20.1, ASME B 16.11, ASME B16.25

Tested to ISO 5208, API 598, PED (97/23/EC)Features/Benefits: QR Code digital asset tracking accessed via mobile device

6E Series valve body can be configured to Cryogenic Globe, Check, Screw Down Non-Return, Gas Globe, Ball Float & Strainer

Minimum level of spares to stock -

330, 334 Series Cryo Brz & SS Wafer Check Valve

Material: Bronze, Brass, AB Brass, Manganese Bronze Applications: Liquid, Gas, and Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure (Bronze): 150# – 1.55 Mpa (225 psi), Non-Shock Cold

300# – 3.45 Mpa (500 psi), Non-Shock ColdMax Working Pressure (Stainless Steel): 150# – 1.90 Mpa (276 psi), Non-Shock Cold

300# – 4.96 Mpa (720 psi), Non-Shock ColdStandards: Degreased, Packed and labelled for Oxygen Services (ASTM G93)

Design accordance with EN12516 part 2 & 4, AS1210, EN1626, ASME B16.24

End Connection: ISO 7-1, ASME B1.20.1

Tested to ISO 5208, API 598

CE Pressure Equipment Directive (97/23/EC)

-

103, 109 Series Cryo Brz & SS 3 Way Diverting Valve

03 Series (Bronze), 109 Series (Stainless Steel), PN50

BSPT, NPT Ends

Material: Bronze, Brass, Manganese Bronze Applications: Liquid, Gas, and Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure: 5.0 Mpa (725 psi), Non-Shock Cold Standards: Design accordance with EN12516 part 1& 2 & 4, ASME B16.34, ASME B16.24

End Connection: ISO 7-1, ASME B1.20.1

Tested to ISO 5208, API 598

CE, Pressure Equipment Directive (97/23/EC) -

104 Series Cryogenic Bronze 4 Way Diverting Valve

104 Series, PN25

BSPT, NPT Ends

Material: Bronze Applications: Liquid, Gas, and Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure: 2.5 Mpa (362.5 psi), Non-Shock Cold Standards: Degreased, Packed for Oxygen Services

Designed in accordance with EN12516 part 2 & 4, AS1210, EN 1626, AS1271, ASME 16.24

End Connection: ISO 7-1, ASME B1.20.1

Tested to ISO 5208, API 598

CE, Pressure Equipment Directive (97/23/EC)

-

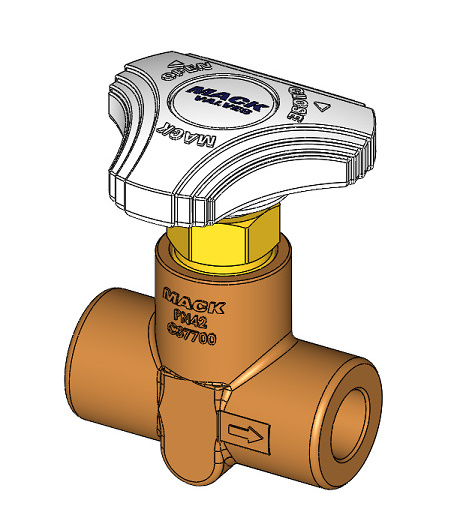

6E Series Type 1 – Cryogenic/Interoperable Globe Valves

Material: Bronze, Stainless steel Media: Cryogenic, Steam, Water, Air & Gases Size Range: 15mm to 50mm Ends: BSPT, NPT, Socket Weld, ANSI 150/300 Working Temperature: -196°C to +120°C Max Working Pressure: 5,000 Kpa Standards: Degreased, packed and labelled for Oxygen Service (ASTM G93)

Design in acc. EN12516 part 1&2, AS1210, EN1626

Ends: ISO 7-1, ASME B1.20.1, ASME B 16.11, ASME B16.25

Tested to ISO 5208, API 598, PED (97/23/EC)Features/Benefits: QR Code digital asset tracking accessed via mobile device

Tamper proof handles

6E Series valve body can be configured to Cryogenic Globe, Check, Screw Down Non-Return, Gas Globe, Ball Float & Strainer

Minimum level of spares to stock

-

773, 779 Series Cryo Brz & SS Pressure Reducing Valve

773 Series (Bronze) & 779 Series (Stainless Steel), PN25

BSPT, NPT Ends

Material: Bronze, Brass, AB Brass, Manganese Bronze Applications: Liquid, Gas, and Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure: 2.5 Mpa (362 psi), Non-Shock Cold Standards: Degreased, Packed and labelled for Oxygen Services (ASTM G93)

Designed in accordance with EN12516 part 1, 2 & 4, AS1210, AS1271, ASME 16.24, ASME B16.34

End Connection: ISO 7-1, ASME B1.20.1

Tested to API 598

CE, Pressure Equipment Directive (97/23/EC)

-

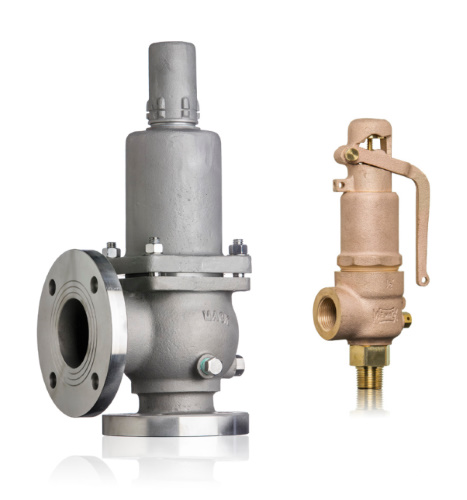

7E Series – Safety/Relief Valves

7E Series – Safety/Relief Valves

Material: Bronze, Stainless steel Media: Cryogenic, Steam, Water, Air & Gases Size Range: 15mm to 150mm Ends: BSPT, NPT, Variety of Flanges Working Temperature: -196°C to + 120°C Max Working Pressure: 15 – 9,000kpa Standards: Degreased, packed and labelled for Oxygen Service (ASTM G93)

Design in acc. AS1271

Tested to API 527Features/Benefits: All springs are Stainless steel

Hard or Soft Seats available

Bolted cover for 50mm and above only

-

1203 Series Cryo Bolted Bonnet Brz Body, Brass Trim SDNR Valve

1203 Series, PN50

BSPT, NPT, Toe Nipple Ends

Material: Bronze, Brass Applications: Liquid, Gas, LNG & Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure: 5.0 Mpa (725 psi), Non-Shock Cold Standards: Degreased, Packed and labelled for Oxygen Services (ASTM G93)

Design accordance with EN12516 part 2 & 4, AS1210, EN1626, ASME B16.24

End Connection: ISO 7-1, ASME B1.20.1

Tested to ISO 5208, API 598

CE, Pressure Equipment Directive (97/23/EC) -

1206, 1209 Series Cryo Bolted Bonnet SS Body SDNR Valve

1206 Series (Brass Trim), 1209 Series (Stainless Steel Trim), PN50

BSPT, NPT, Socket Weld, Butt Weld Ends

Material: Brass Applications: Liquid, Gas, LNG & Oxygen Services Working Temperature: -196°C to +190°C Max Working Pressure: 5.0 Mpa (725 psi), Non-Shock Cold Standards: Degreased, Packed and labelled for Oxygen Services (ASTM G93)

Design accordance with EN12516 part 1& 2, AS1210, EN1626, ASME B16.34

End Connection: ISO 7-1, ASME B1.20.1, ASME B 16.11, ASME B16.25

Tested to ISO 5208, API 598

CE, Pressure Equipment Directive (97/23/EC)

-

Y Type Strainers

Series: 6708, 6748, 6788

Sizes: 1/2” (DN15) – 2” (DN50) Body: Gun Metal, Stainless steel, Cast Steel Ends: BSPT

-

LC SERIES – Short Stem Liquid Cylinder Valve

Material: Brass Applications: Control filling and withdrawal of media from liquid cylinder vessels Media: Cryogenic, Steam, Water, Air & Gases Size Ranges: 8mm to 15mm Ends: NPT, BSPT/Stub Ends Working Temperatures: -196°C to +75°C Max Working Pressure: 4200kPa Standards: Degreased, packed and labelled for Oxygen Service in accordance with ASTM G93

Approved for TPED, ADR/RID in accordance with EN1626

Tested to EN12266-1

Type Tested to EN1626Features/Benefits: Spring loaded to take account of any wear

-

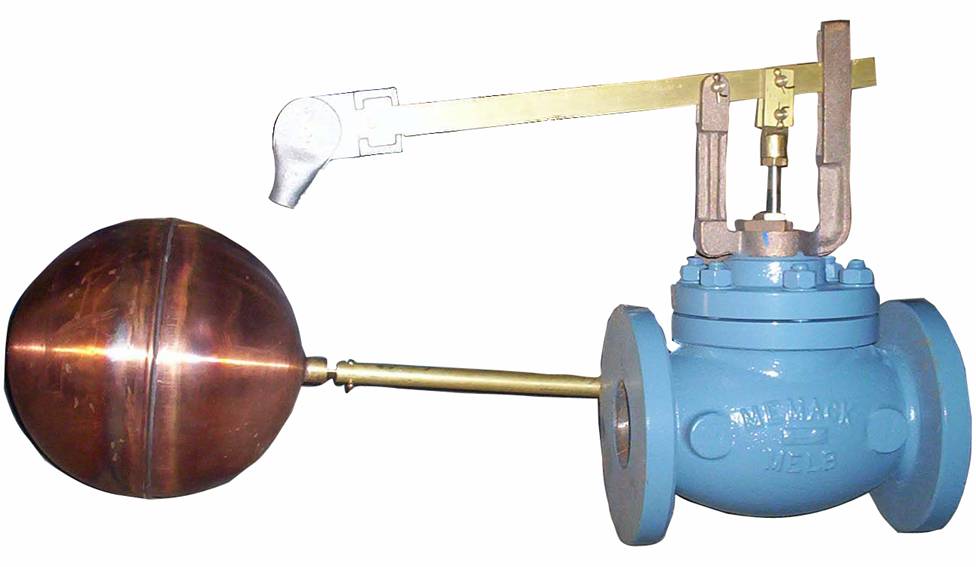

9138, 9198 Series Ball Float Valves, Ball Float Valves

9138 (Gun Metal), 9198 (Stainless Steel)

BSPT Ends

Material: Gun Metal, Stainless Steel Working Temperature: 93°C, 200°F Max Working Pressure: 1720 kPa, (250psi) -

9130, 9132 Series Ball Float Valves Flanged, Ball Float Valves

9130 (gunmetal BSTE), 9131A (gunmetal ANSI 150), 9132 (gunmetal BSTH), 9171A (cast steel ANSI 150)

B.S.T. E & H, ANSI 150

Material: Gun Metal, Cast Steel Working Temperature: 93°C, 200°F Max Working Pressure: 1400 – 1720 kPa (203 – 250 psi) pending size

-

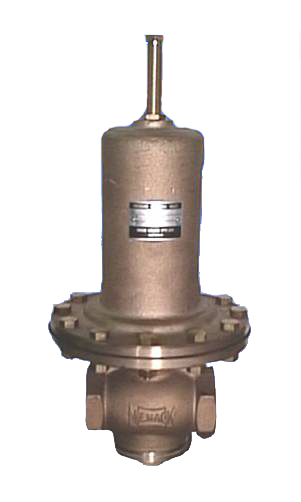

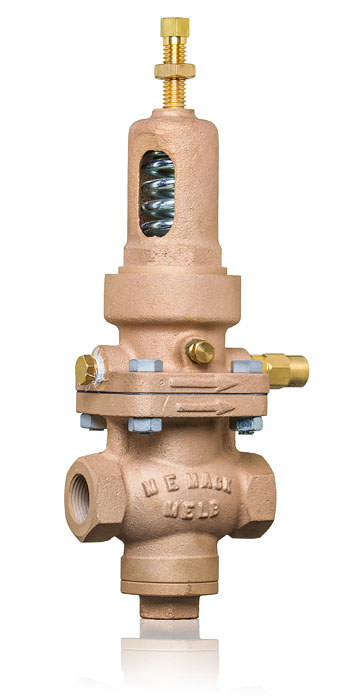

7838, 7898 Series Reducing Valve

7838 (Gun Metal), 7898 (Stainless Steel)

BSPT Ends

Material: Gun Metal, Stainless Steel Applications: Gas, Water & Liquids Working Temperature: 93°C, 200°F Working Pressure: From 70-2400 kPa (depending on size)

-

7038, 7098 Series Surplus Valves

7038 (gunmetal), 7048 (gunmetal). 7098 (stainless steel)

BSPT Ends

Material: Gun Metal, Stainless Steel Max Working Temperature: 190°C 374°F Max Working Pressure: 1725kPa – 2520 kPa (250 psi – 365 psi) pending size